Surface Technology

We offer customer specific surfaces

By means of the etching and immersion process that has been specially developed by EuropTec, we are able to develop customised glass for defined surface qualities, depths of roughness or gloss values. In this process the characteristics, uniformity and reproducibility can be optimally directed even over large surfaces. Our particular competencies lie in the areas of light scattering, structuring and surface engineering.

Surface Engineering

Functional glass must have a flawless surface, so that coatings take perfectly, for example. With our etching processes we can clean and chemically polish glass or increase the breaking resistance of the glass by means of acid treatment. In this process, any damage to the surface of the glass that occurs during sandblasting or CNC treatment, for example, is smoothed away. Our acid bath also cleans glass of any chemical impurities that are not visible to the naked eye, or levels out microfine cracks that could quickly result in rupture failures in the case of stress or a change of temperature.

In addition, using a specially developed etching process, we can remove manufacturing traces of tin from the glass bath side/tin side and thus prevent warping of glass surfaces during the chemical hardening process.

Structuring

Etched surfaces according to precise customer specifications optimise the writing experience on script discerning displays, for example. Structured and/or etched surfaces are haptically optimised, resistant to fingerprints (anti-fingerprint) and similar contamination and thus ideal for touch applications. In addition, by means of a specially developed etching process we can remove tin particles that are created during the manufacturing process from the glass bath side/tin side and thus prevent warping of glass surfaces during the chemical hardening process.

The high quality appearance of our products is achieved through special surface characteristics with optimised cleaning abilities. The special surface structures of our glasses support the functionality of a number of applications – either as writable projection boards for beamer presentations or industrial displays.

With modern computers and telecommunication systems, high quality operating elements with touch function are increasingly being used. These have to be AR coated, touch sensitive, pleasant to the touch and easy to clean when in constant use. Our etched glass meet these high requirements and the anti-fingerprint effect in particular is a major advantage when it comes to anti-reflective products for touch applications that have to be optically interference free.

Technical data:

Delivery conditions:

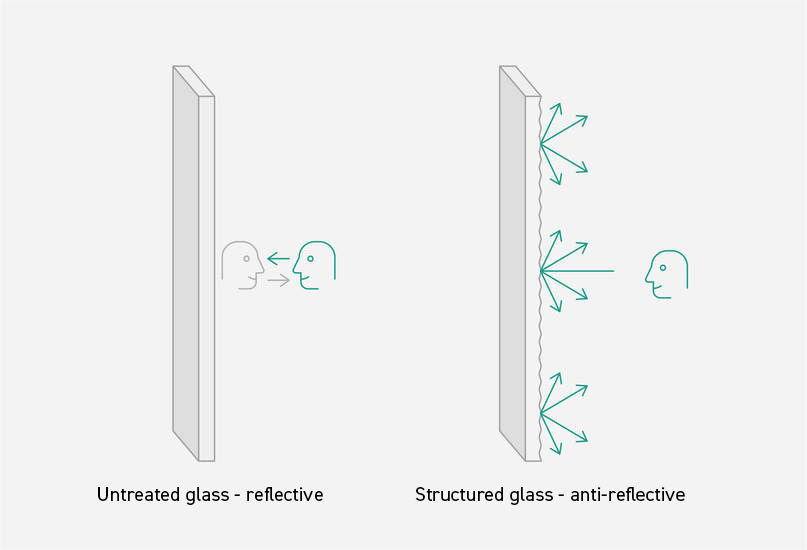

Scattering

Whilst untreated glass simply reflects light and creates annoying reflections, the light is definitively scattered by our structured glass surfaces. This almost completely eliminates any interference from glare and mirroring effects.

Anti-Reflection

LUXAR® offers an anti-reflective coating for flat glass that is interference free. Reflections on the surface of the glass of more than 8% for uncoated glass are reduced to 0.5 % and light transmission is improved at the same time, thereby significantly improving the brilliance of the image as the colours remain true.

Mirror

Highly-reflective surface mirrors from EuropTec offer maximum light reflection with ultimate imaging quality without creating a double image. This kind of surface mirror is optimised for optical applications and guarantees excellent image quality in digital rear projection systems and in all applications with the highest requirements for reflected light.

One-way mirror

One-way mirrors consist of mirrored glass on one side and a transparent rear side, and are ideal for applications such as where surveillance takes place and the person carrying out the surveillance is not visible. One-way mirrors reflect neutral colours and also offer authentic transmission colour. They can be further processed to produce single-panel safety glass or multilayer safety glass. The one-way mirrors from EuropTec offer 1%, 12% or 20% light transmission. The higher the level of required light transmission, the lower the reflection of a one-way mirror.

Split mirrors

Split mirrors are semi-reflecting mirrors that reflect and transmit light. An optical-interference coating guarantees high abrasion resistance alongside the neutral-coloured reflection and transmission. Split mirrors can be designed with single-panel safety glass or multilayer safety glass. They are widely used in teleprompters.